By Michael Pearsall, P.Eng., CVS, CVM, FICE, FEC

As promised in the last column, I am pleased to have guest columnists from the great folks at VMS to tell you more about their work on NCHRP 19-11 and the Value Management System Tool for Transportation Projects. If you didn’t get the opportunity to take in Robert Stewart’s presentation The Development of a Value Management System Tool for Transportation Projects in Philadelphia, or if you enjoyed it so much you want more, then you are in luck.

I want to reiterate what I said in my September column, that this was developed with the objective of improving the delivery of transportation projects and I think we can all benefit from it.

The following is by my guest columnists Robert Stewart, CVS-Life, FSAVE and Greg Brink, CVS.

Integrated Value Management and the Value Management System Tool

Recent research was conducted exploring value enhancing tools and techniques for transportation projects for the National Cooperative Highway Research Program (NCHRP) under Project 19-11. The NCHRP is one of the research programs within the Transportation Research Board of the National Academies of Sciences, Engineering, and Medicine.

Research began in the summer of 2015 and concluded in January 2017. The research team was comprised of individuals from Value Management Strategies, Inc. (VMS) and Portland State University’s (PSU) Department of Engineering and Technology Management (ETM). The objective of this research was to gather and analyze information on existing processes currently being applied and utilized by public transportation agencies. Key processes that were the primary focus include Value Engineering (VE), Risk Analysis (RA) and Constructability Review (CR). Other innovative processes and techniques to improve the delivery of transportation projects were also considered.

The research team reviewed the VE, RA and CR programs for over fifty public transportation agencies using surveys and literature reviews. This information was analyzed and the conclusions were used to guide the research team in developing a Value Management System tool that can be applied by public project delivery teams to improve value and foster innovation. A sophisticated MS Excel workbook, a transportation project example and a series of training videos were developed as a part of this effort. These items can be accessed at the following link http://www.trb.org/Main/Blurbs/176394.aspx.

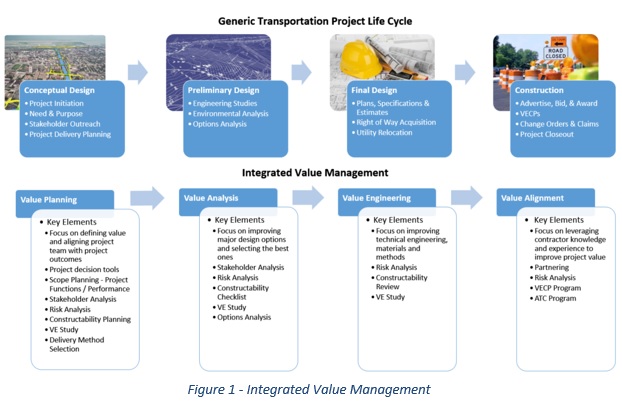

As part of the efforts, the research team developed an integrated process that incorporates Value Engineering, Risk Analysis and Constructability Review along with additional tools and techniques to enhance communication, collaboration and innovation for project delivery teams. Since the focus is on total value improvement, the research team has titled this process Integrated Value Management. In order to assist departments of transportation in maximizing opportunities to inject good value into their projects, the Value Management System tool was created around the Integrated Value Management process.

The application of Integrated Value Management and conducting of various types of analyses through the use of the Value Management System tool offers benefits to departments of transportation by providing a structured, repeatable, and comprehensive approach to injecting value into transportation projects throughout project delivery. Figure 1 below provides a visual outline of how this new process aligns with a generic project delivery life cycle for transportation projects. It highlights key elements and provides a basic blueprint to guide and assist project delivery teams in maximizing the value of their projects.

This overarching process is supported by the Value Management System tool which has been developed using Microsoft Excel. This integrated MS Excel workbook includes the following value enhancing processes:

- Stakeholder Analysis

- Decision Analysis

- Risk Analysis

- Constructability Review

- Value Engineering

- Project Delivery Method Selection

The MS Excel workbook is designed to allow any combination of the processes to be used for a project. Further, it is customizable to allow some worksheets to be modified to better align with individual agency standards.

Instruction on the use of the Value Management System tool is provided through a series of seven instructional videos that walk users through a completed example transportation project using the tool. The videos, along with their durations, are as follows:

- Introduction (6:49)

- Stakeholder Analysis (9:58)

- Decision Analysis (18:21)

- Risk Analysis (13:27)

- Constructability Review (4:55)

- Value Engineering (9:59)

- Project Delivery Method Selection (6:35)

The example transportation project, titled the Davis Road Bridge Replacement Project, considers an actual project that includes pavement, bridge, and traffic control elements. Users should be able to easily relate to this example and how the tool is used to help improve project value and develop innovative solutions. This tool and the associated techniques are still relevant and applicable to all types of construction project delivery, but the primary focus is on transportation projects.

The research suggests that, more than ever, fostering solid communication and collaboration within and amongst project teams is essential in delivering projects on time and within budget. Existing tools currently utilized by DOTs can be better leveraged by seeking to integrate them into a comprehensive platform, ensuring proper technique is applied, and by enhancing group decision making. The Value Management System tool integrates many such tools as a comprehensive platform to manage scope, control costs, and maintain schedule while maximizing performance and effectively managing risk.

The proposed methods and tools emanating from this research should be implemented by ensuring proper training and dissemination. Implementing the changes in thinking and behavior suggested in this research requires cultural and organizational change. In addition, changes to processes and delivery plans may also need to be adapted and changed. This will no doubt prove to be the biggest challenge to overcome in supporting project teams in delivering good value.

– Robert Stewart and Greg Brink

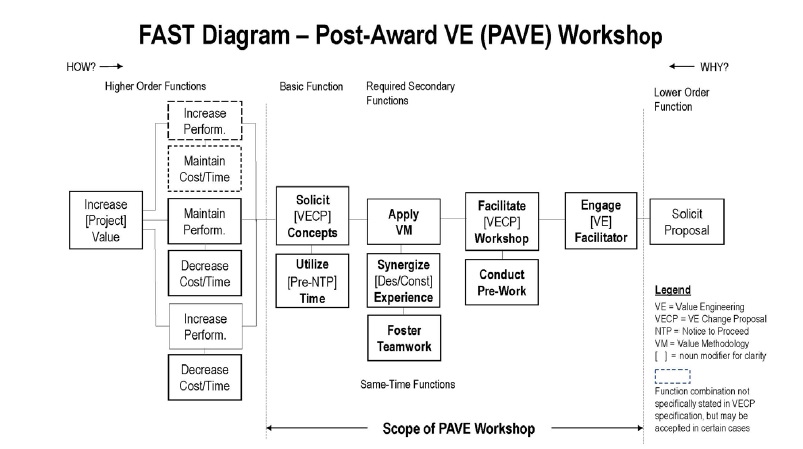

Some of you may recall from last month that I put out a fun call for you to try creating your own FAST diagram for PAVE. As promised, below is Warren Knoles’ FAST diagram for you to compare with the one you drafted. I hope you had fun with the FAST diagram exercise and I will look for some more fun exercises we can do in future columns. We had discussed this diagram over lunch one day at the VA Canada conference in Montreal and as Scot McClintock aptly pointed out – likely six tables of CVS’s could come up with six slightly different versions and they would all be correct, so if yours is different, don’t see either one as right or wrong. Some commentary to support our version is provided following the diagram.

The author, in collaboration with the Transportation Column editor, prepared the FAST diagram for the PAVE workshop process as shown. This function diagram is explained as follows:

- Higher Order Functions. The highest order function is “Increase [Project] Value,” which is the goal of all MoDOT projects as expressed on the MoDOT web site: “Deliver Transportation Solutions of Great Value.” The next combinations of higher order functions express the intent of the MoDOT standard specification for value engineering change proposals (VECPs). The function combination in the dashed function boxes is one that is not specifically stated in the VECP specification, but may be accepted in certain cases.

- Basic Function. The basic function of the PAVE workshop process is to “Solicit [VECP] Concepts” from the contractor and rest of the workshop team. This is a key feature of the process which distinguishes it from the normal VECP process. MoDOT is proactively soliciting VECP submittals that perform the higher order functions rather than wait for the contractor to submit them.

Another key feature (shown as a same-time function) is to “Utilize [Pre-Notice-to-Proceed] Time.” This function solicits VECP ideas just after award and prior to the notice to proceed (NTP). This allows ideas to be vetted by MoDOT using non-critical-path time, thus helping prevent construction delays that any accepted VECPs could cause once construction is underway.

These two features address two of the reasons for the national decline in VECPs: DOT resistance to VECPs and DOTs taking too much time reviewing proposed VECPs.

- Required Secondary Functions. The first required secondary function is “Apply VM (value methodology).” This function is the PAVE process’s most important feature because it addresses one of the main reasons for DOT resistance to VECPs: VECPs that do not provide equivalent function, or the DOT’s inability to determine if the VECP provides equivalent function. The value methodology clearly describes the key functions of the baseline project and provides an efficient and effective way to screen and evaluate concepts generated by the workshop team to demonstrate function equivalency. This prevents both the contractor and the DOT from wasting time on un-approvable VECP proposals that do not provide equivalent function. The workshop also provides a discrete deliverable that contains a screened and evaluated list of ideas along with clear guidance on what is required to obtain approval of a VECP coming from one of the ideas on the list. The contractor is also offered the opportunity to express “no interest” during the workshop and is under no obligation to submit a VECP for ideas on the list.

Same-time functions are “Synergize [Design/Construction] Experience” and “Foster Teamwork.” Synergizing the DOT’s design experience with the contractor’s construction experience is a powerful combination to identify designs that contain hidden consequential costs such as costly fabrication, transportation, phasing and means/methods. Theses costs can sometimes be eliminated or reduced by contractor alternative VECP concepts. The “Foster Teamwork” function helps create a unified DOT/contractor team spirit before the job starts.

The next required secondary function is “Facilitate [VECP] Workshop.” Experienced VE facilitation keeps the meeting efficient and effective using the value methodology and makes sure that ideas are adequately evaluated, and a concise deliverable is produced. “Conduct Pre-Work” is shown as a same-time function event though it precedes facilitation in time, since the pre-work is an essential part of the PAVE workshop.

The last required secondary function is “Engage [VE] Facilitator.” Though it is technically not a part of the workshop, it is shown to the left of the scope line because engagement of an experienced and trained VE facilitator, along with a clear scope, budget and schedule is required for a successful workshop facilitation.

- Lower Order Function. “Solicit Proposal” is the lower order function, which starts the PAVE workshop process. This function assumes that the owner needs to engage a qualified VE consultant to facilitate the PAVE workshop. If the facilitation is to be performed by an in-house representative, then this function could be “Select Facilitator” and the first function to the left could be “Assign Facilitator.”

Until the next issue, I would like to continue to encourage any transportation professional out there who would like to share their stories to contact me at mike.pearsall@ontario.ca.