By Ferenc Nadasdi, CVS-Life, PhD, FSAVE and Kornelia Vamosi, PhD

The main characteristics of the furniture factory

The business scope of the company is diversified. It deals with the manufacturing, distribution and delivery of furniture. It has a wide range of products and mainly offers mid-range, high quality, but affordable furnishings. It has a reseller network covering the entire territory of Hungary. The company has 11 stores. The management has a dual task: besides improving quality, it has to boost its production and operations.

The project was completed in cooperation with the company and the University of Dunaujvaros. The professors of the University volunteered to supervise the project. Other members of the team were: a designer, the Head of the Technology Department, the Head of the Operation Department, a cost engineer; all employees of the factory. During the process, other specialists from the company assisted when specific problems arose. The management of the factory assisted in collecting necessary information and supervised the progress of the project.

The goal of the project

Main goal: improving the market position of the product

Sub-goals:

- Better compliance with user and manufacturer needs

- Elimination of quality problems arising from production

- Reducing operational costs

- Reducing operation time

- Reducing the material and energy consumption of the technology

- Improving the capacity utilization of the main manufacturing process or equipment

- Replacing heavy physical work

- Improving health, safety and environmental protection

The subject of the project

The subject of our Value Analysis is the process of furniture production. The main raw material is the prelaminated particle board, which is created by pressing decor paper on the plain particle board by thermal pressing. This raw material is cut to sizes by a computer controlled cutting machine following a pre-defined pattern. After splitting/cutting, the semi-finished products are transferred into the CNC machining center, where the possible kerfs, roundings and drills are performed, which secure the matching and appearance of the final product. (Stewart, R. B. 2005)

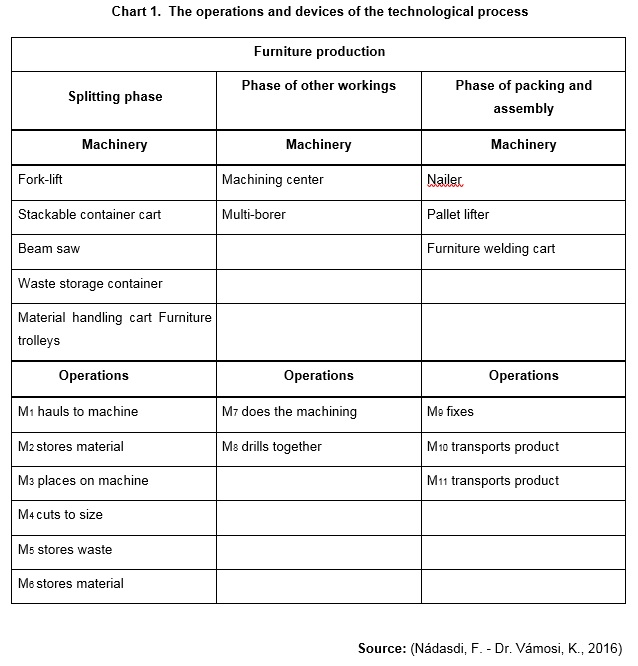

Information about the technological process

The following chart summarizes the operations and equipment of furniture production:

DEMAND ANALYSIS

The authors decided that it was essential to analyze the product itself as a first step to identify possible unnecessary functions and costs. Based on our experience, it often happens that it is necessary to combine technological changes with product design changes as well.

Customer demands towards furniture are the following:

- Should be of the right size

- Can be easily packed

- Drawers should be easy to slide

- Should be aesthetic

- Should be durable

- Should be easy to move

- Should be easy to ship/transport

- Should be wear-proof

- Should be fashionable

- Should be safe

- Good value for money

- Acceptable price

- Easy to install

- Environmentally friendly

- Recyclable

- Should be of the right color

Demands towards technology are the following:

- Should be flexibly customized

- Should yield the exact size

- Should secure quick transition

- Should provide impeccable appearance

- Should result in a quality product

- Should be economic

- Maintenance should be transparent

- It must not have adverse effects on the environment

- Should make the product suitable for distribution on the market

- Should be easy to install

- Should be easy to pack

- Should be easy to transfer without any damage

- Should be easy to store

(Bolton, James D. at al, 2004), (Bytheway, Charles W. 2007)

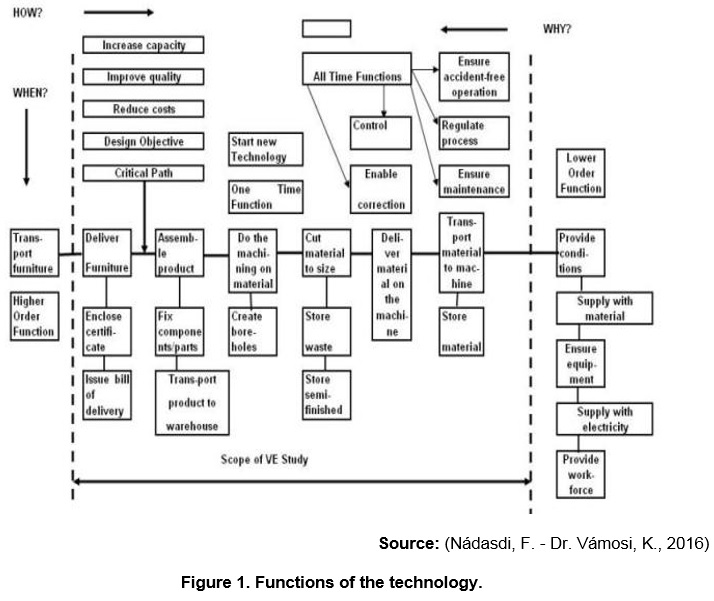

Function analysis

First, we have defined the functions of the product, then of the technology starting from consumer/user demands.

Functions of the product:

F1: Provides visual experience

F1.1. Conforms to environment

F1.2. Provides a pleasing shape

F2: Provides storage space

F2.1. Has the right dimensions

F2.2. Has closure and opening

F3: Ensures easy usage

F4: Ensures quality

F4.1. Ensures maintainability, cleaning

F4.2. Has longevity

F5: Ensures expected appearance

F5.1. Delivers the expected color scheme

F5.2. Conforms to the place/ambience

F6: Ensures transportability

(Clancy, D. F. – Dennnis L. M. 2004), (Kaufman, J. J. – Woodhead, R. 2006)

These are general functions which emerge in case of furniture. Further functions might arise upon analyzing specific types of furniture.

The method of Value Analysis has been utilized during technology design. Defining functions and function costs enabled the development of an efficient technology. The furniture factory has become more economic and more productive by utilizing the new opportunities which the new machines provide and by introducing the new technology. With the increase in size accuracy, the customer can assemble the products and the expertise of a carpenter is not required. This fact made the production of flat-pack products possible and many furniture products are sold in a semi-finished condition in cardboard boxes. As a result to the flat-pack formation, the utilization of warehouses has improved to a great extent. The improvement of technology resulted in extra capacity, which enabled the development and design of new products which have their places in the production.

Prime cost vs. function cost

At times a professional debate sparks off between the engineers developing the technology and the Value Analyst expert during choosing certain function carriers. For instance, there are two kinds of solutions when polishing surfaces. One of them is using sandpaper. The sandpaper is fixed upon a rotating disk. The other solution is the usage of a milling cutter, which polishes the surface with a rotating motion. Both solutions can result in similar surface quality. Technologists preferred sandpaper, referring to its low prime cost. 1 m2 sandpaper costs 0,1 USD, while a milling cutter costs 20 USD. However, on one m2 surface to be machined, the use of sandpaper was 10 times more expensive than using the milling cutter.

Value Analysis does not use the expressions ‘cheap’ or ‘expensive’ and/or ‘component’. Value Analysis uses the expression ‘Function cost’, or rather that is what it defines and it suggests a decision during which it should be taken into account!

EXPECTED RESULTS

The company can improve product quality, fully comply with consumer and manufacturer demands, grow its capacity, reduce costs, and widen their presence in the domestic and the international markets by implementing the new technology. Some examples of the modernization of the equipment (Picture 3., Picture 4., Picture 5., Picture 6.)

Value Analysis of the tools of furniture production technology

We have analyzed the tools that are necessary for the operation of the equipment in the design of the technology. We have set the following goals when choosing the tools:

- Eliminating quality problems arising during production

- Reducing operational costs

- Reducing the material and energy consumption of the technology

- Improving capacity utilization of the main production process and equipment

- Enhancing productivity

We have examined the following groups in the field of tools based on basic commodity:

- Diamond tools

- CBN cubic boron nitride

- PCD polycrystalline diamond

- Composites

- Coated tools (Titanium nitride TiN; Titanium carbonitride TiCN; Ceramics Al2O3)

The comparison of the tools was carried out with the help of function analysis.

The functions of the tools (highlighting woodworking chisels):

F0 Disintegrates material

F1 Improves the quality of the work piece

F11 Ensures edge quality

F12 Ensures cutting quality

F2 Easy to replace

F2.1. Reduces downtime

F2.2. Fits perfectly to equipment

F3 Enhances work safety

F3.1. Ensures silent mode

F3.2. Protects body parts

F4 Has longevity

F4.1. Resists abrasion

F4.2. Resists deformation

After executing the function analysis and determining function costs, we discovered that the prime cost of diamond-based tools is the highest. At the same time, the longevity of the diamond-based tools is several times more than that of the other tools. When using diamond-based tools, downtime is significantly reduced and the machining of the components results in better quality than in the case of working with other tools. Company management decided to purchase diamond-based tools and their decision was based on Value Analysis. The firm was buying expensive equipment and was given several offers. The offers had difference in functions and prices. Management usually tends to choose the lowest priced offer. Function analysis was utilized in choosing the appropriate equipment to support the technological development.

Summary

The application of Value Analysis in furniture production draws up several practical suggestions, of which company management and their experts have not thought of before. The implementation of the suggestions may improve the position of the company in both the domestic and international markets. Company management chose several of the suggested technological solutions based on their available budget.

(Miles, L.D., 1972), (Sato, Y. – Kaufman, J. J., 2005)

Bibliography

Bolton, James D. – Nayak, Bijay K. (2004): Implementation of Value Management with the Manufacturing Supplier Community. 44. SAVE International Conference, Montreal, CANADA.

Bytheway, Charles W. (2007): FAST Creativity & Innovation. J. ROSS PUBLISING, USA.

Clancy, D. F. – Dennis L. M. (2004): The Innovation and Application of the Value – Based Design Charette – Start Your Project Right to Ensure a Successful Completion. SAVE International Conference, USA.

Nádasdi, Ferenc – Gallai, László (1) (2008): Value Analysis of the technology of furniture production. Case study. College of Dunaújváros. The obtained results were further developed by the authors.

Nádasdi, Ferenc – Gallai, László (2) (2008): Value Analysis of the tools of the technology of furniture production. Case study. College of Dunaújváros. The obtained results were further developed by the authors.

Nádasdi, F. – Dr. Vámosi, K. (2016): Value Analysis of the tools of the technology of furniture production. Case study. University of Dunaújváros. HUNGARY

Kaufman, J. J. – Woodhead, R. (2006): Stimulating Innovation in Products and Services with Function Analysis and Mapping. WILEY INTERSCIENCE, USA.

Miles, L.D. (1972): Techniques of Value Analysis and Engineering. Mc.Graw-Hill Book Company, New York, USA.

Sato, Y. – Kaufman, J. J. (2005): Value Analysis Tear – Down: A New Process for Product Development and Innovation. Industrial Press Inc. and Society of Manufacturing Engineers, New York, USA.

Stewart, R. B. (2005): Fundamentals of Value Methodology. Xlibris Corporation, USA.